Plasma Gasification

Many kind of Waste in the world are managed with landfill .

But Landfills are not the best solution to dispose waste. They cause many problems in the years for enviromental pollution.

Definitive solution to solve disposal waste is the installation of a plasma Gasification near the landfill.

So, Plasma Gasification may process every day waste received from collection, and partial waste from landfill, until the complete disposal of the same.

This Solution solve enviromental problems and cost for management landfill in the years.

The Management of Hazardous Waste in the World, is a Big Enviromental Problem to solve urgently.

We can enclose in the type of Hazardous waste: Medical Waste, Industrial Waste, Petrochemical Waste, Asbestos Waste, Pharmaceutical Waste, Tires Waste, Sludge processing Tanning Waste, Ashes from Inceneritor and others.

Our Plasma Gasification is able to

Medical Waste Medical Waste |

|

Pharmaceutical Waste Pharmaceutical Waste |

|

Chemical and Petrochemical Waste Chemical and Petrochemical Waste |

|

Asbestos Waste Asbestos Waste |

|

Ashes from Inceneritor Ashes from Inceneritor |

Tires Waste Tires Waste |

|

Sludge Processing Tanning Waste Sludge Processing Tanning Waste |

|

Electronic Components Waste Electronic Components Waste |

|

Our Plasma Gasification is able to process any kind of waste toghether .

Disposal of Municipal Solid Waste is the most Urgent Enviromental Problem to solve in the World.

The problem of Waste Management affects all countries around the world, and with the increasing population, the problem of waste management increases exponentially.

Bad Management of Municipal solid Waste is the reason of many Enviromemental Problems as pollution of the air, pollution of groundwater , pollution of crops, pollution of land and pet food.

This Big Enviromental Problem must be solved very urgently because many people have health problems and resulting enormous costs to the entity that manages the medical costs.

Until today many countries put Municipal Solid Waste in the Landfills. But this do not solve the problem of waste because landfill will be a cost for many years and the landflill will issu pollution in the land, in the air and in the groundwater.

Our Company can offer you all support to Financing the construction of a Waste Plasma Gasification Plant with Molecular Dissociation Technology.

Our Company is Partner of Important Bank Groups which are able to Financing all the amount necessary for the construction of the Waste Plasma Gasification.

Ask us all informations if you are interested to do the investment.

After you have accepted our offer we need to make a Feasibility Study to have the possibility to give you the final detailed offer and a Business Plan where you can see the return of investment.

With the Business plan you have the complete situation of the return of investment which usually is very fast respect to others technologic solutions of waste process , as inceneritor.

Our experience shows that the return of investment for the construction of a Waste Plasma Gasification with molecular dissociation technology is about 4-5 years.

Our Plasma Gasification can recover 95% of waste as energy , or others subproducts as fuel.

Ask us un Offer

To ask us un offer to install a Plasma Gasification with Molecular Dissociation System you must respect the follows procedures:

1) You must send us a LOI

You must send us a Letter of Intent with all company details , enclosed copy of passport of legal representative of the company adn details of your request.

If you contact us , we will send you LOI module to complete.

2) You must send us reply to a questionnaire we will give you.

In the questionnaire there are very important informations that will give us the possibility to make un offer for you , to install a Plasma Gasification Plant or Molecular Dissociation such us such as the place where you want install the plasma gasification, how many tons a day you need to process, which kind of waste you need to process, how many ton of waste produces the people which lives in the area where you want install the plasma gasification etc.....

You will find more others details in the questionnaire.

This introductory picture require no comment, but should make us reflect on the necessity to URGENTLY change the waste management in the world .

The problem of Waste Management affects all countries around the world, and with the increasing population, the problem of waste management increases exponentially.

Each country chooses different systems to solve this problem from the collection of waste to the recycling materials but until today, anyonee has proven effective.

Our Company offers the solution to permanently solve enviromental problems with good solution of waste management:

The Waste Plasma Gasification plant for waste process ,with Molecular Dissociation System.

The Waste Plasma Gasification plant with Molecular Dissociation Technology , is able to process at the same time any kind of waste, such as municipal solid waste, construction and demolition debris, scrap from cars, coal ash, tyres, biomasses, incinerator waste, liquids and sludge etc....

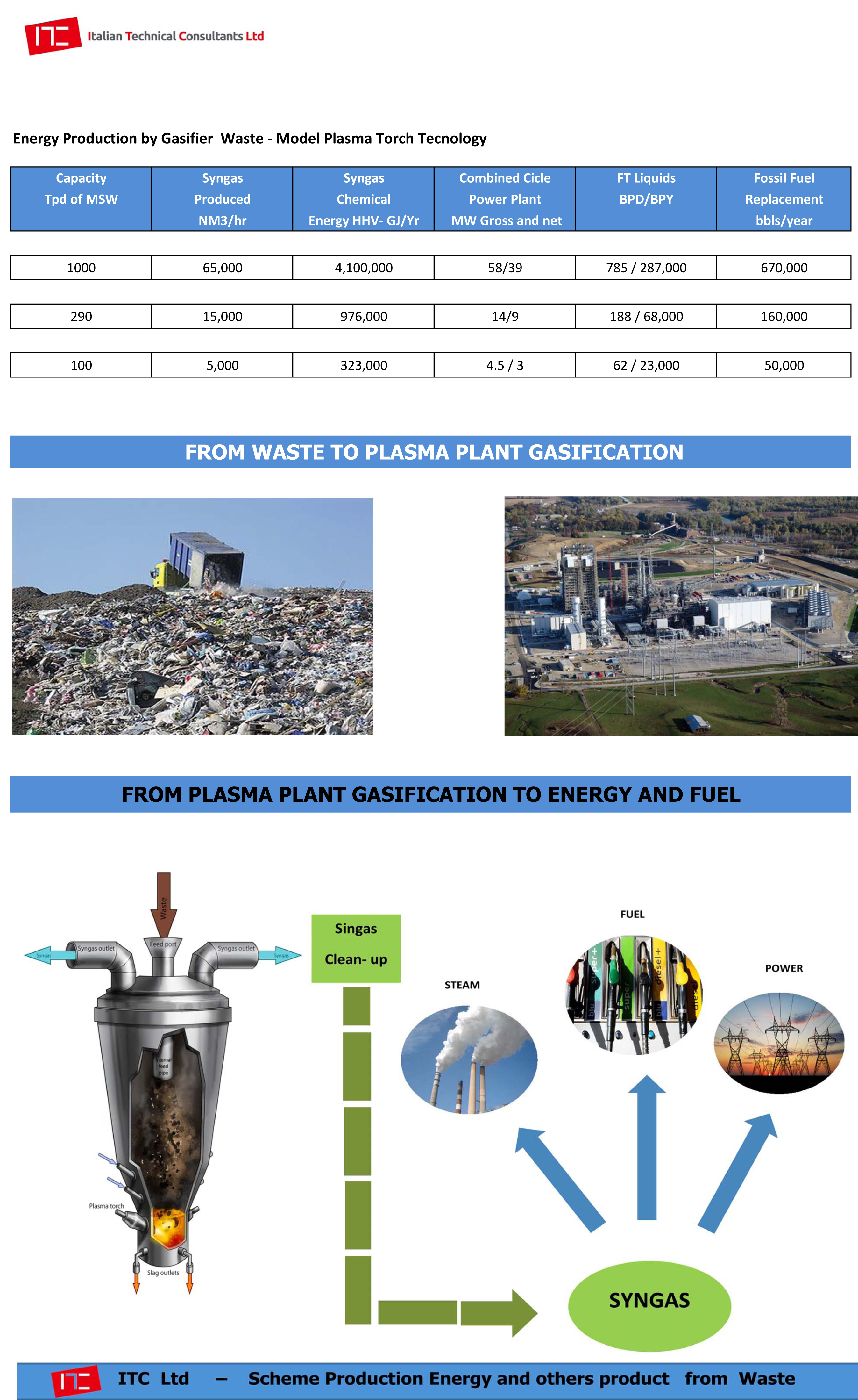

After collection, waste are processed in a chamber of treatment with the Plasma Torch.

The Plasma Torch produces very high temperatures which are able to do the molecular dissociation of all waste taking them back to their original composition.

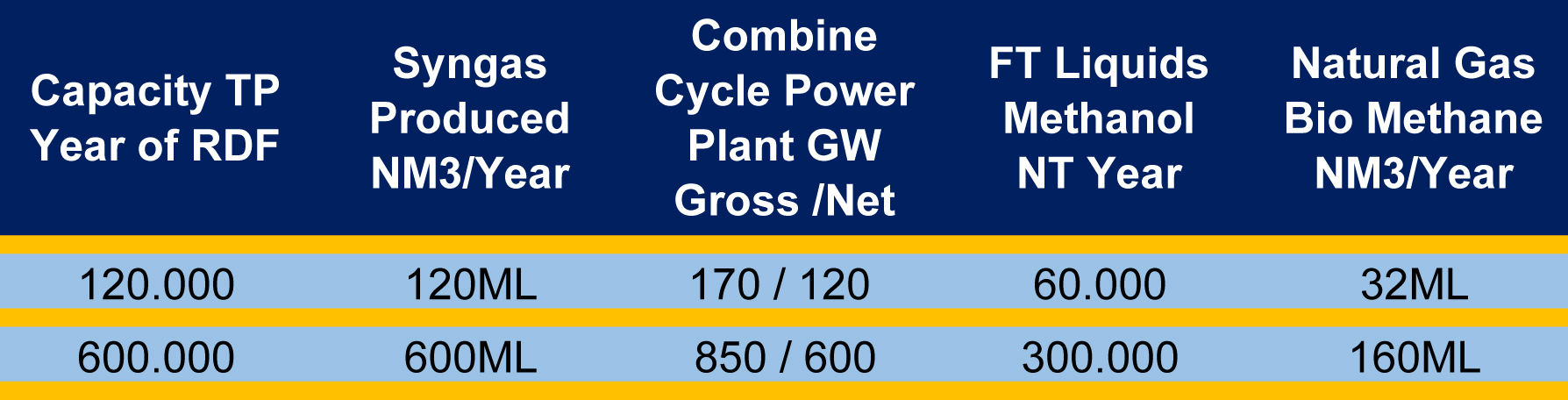

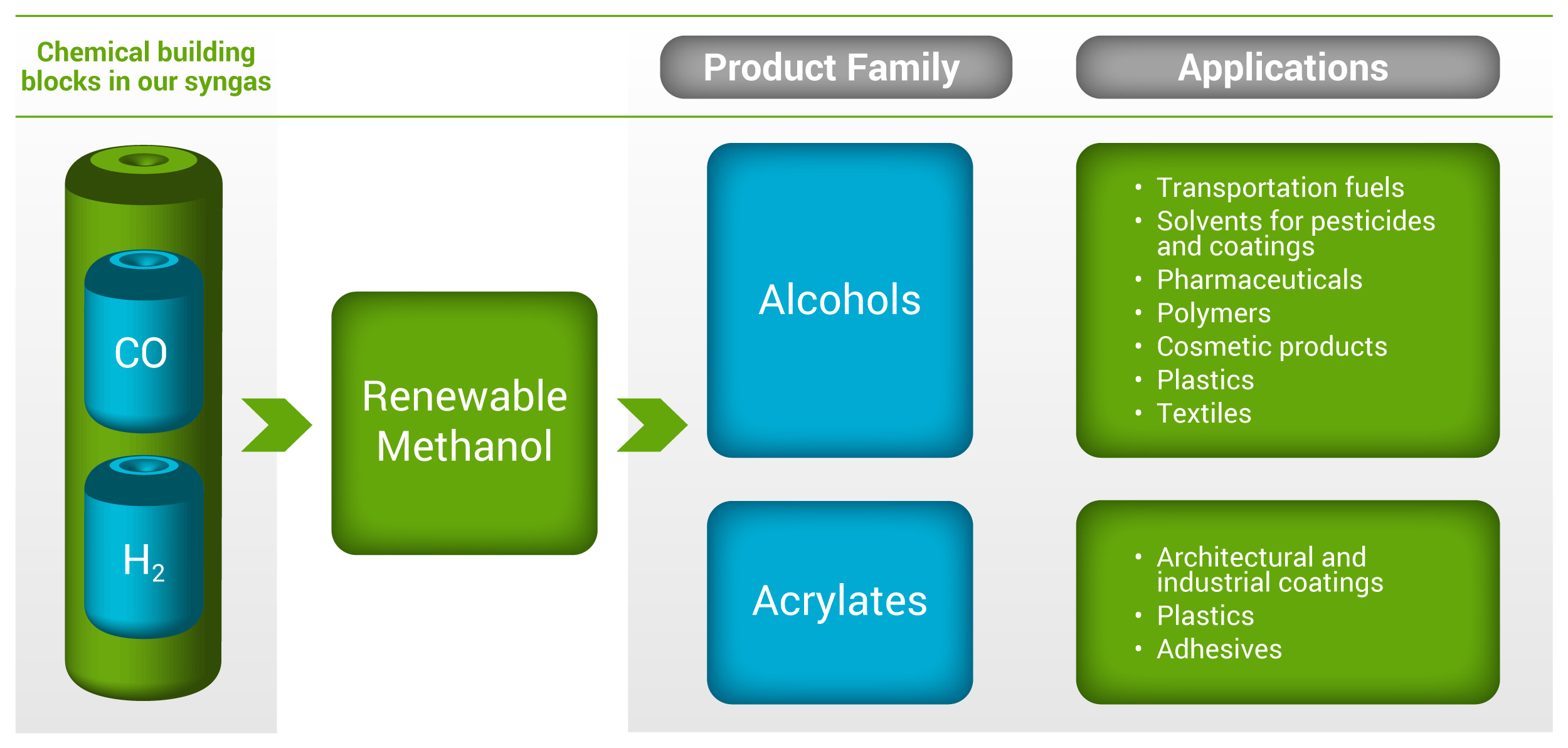

The waste process produces Syngas, which is cleaned from dangerous particles.Then Syngas will used to produce electric energy or fuels .

The heavy elements such as metals or sludge, which cannot be transformed into Syngas, are deposited on the bottom of the treatment chamber and are separated and recovered via sieves (gold, silver, for example contained in the batteries or in the electronic component circuits etc…).

The Syngas clean-up process allows to remove any undesired chemical substances for the prevention of damage to the well-being of man and the environment. On leaving the gasification reactor, the syngas is quickly cooled and the particulate is removed by mixing with water in a spraying tower (Venturi or scrubber effect). Further removal of the particulate takes place in an electrostatic precipitator in a humid environment.

From Wastes to other energy products: Syngas > Methanol

Methanol, or methyl alcohol, is the simplest alcohol, with the chemical formula CH3OH (often written as “MeOH”). It has also been known as wood alcohol, wood spirits, spirit of wood, and wood naphtha, because it used to be produced via pyrolysis of wood. This “spirit of wood” was a key ingredient in Eastman’s process for manufacturing Kodak photographic film. Today, methanol is a widely used commodity chemical, which is used directly, as well as a feedstock for the production of a wide range of other alcohols, liquid fuels, chemicals and plastics

Methanol is primarily used in making other chemicals. About 40% of methanol produced is converted to formaldehyde, which is then converted to other products such as plastics, paints, explosives, and resin-based adhesives used in the manufacture of plywood and wood products.

Today, most methanol is produced using natural gas (methane) as the feedstock.

The second reaction above uses catalysts to assist in the reaction to combine the single CO and the two H2 molecules to form the desired methanol product. This reaction is exothermic, creating a significant source of heat that is typically used elsewhere in the manufacturing plant to generate steam and/or electricity. The ratio of H2 to CO is specific for different downstreamprocesses (seeSyngas ProductionandDownstream Conversion Processes). For methanolsynthesis, the ratio is 2:1. Fortunately, the steam methane reforming step shown in Reaction #1 above produces exactly the ratio (2:1) required for methanol synthesis.

Municipal Solid Waste ;

Pharmaceutical waste and sludge;

Hospital waste;

Chemical waste and sludge from chemical treatments;

Industrial waste containing chlorine, sulphur, etc.;

Industrial Oils and tank washing sludge residues;

Special electronic waste (computers, monitors, household appliances, etc);

Batteries, acids;

Explosive waste and waste containing phosphorus;

Military Waste;

Fly Ash and bottom ash;

Tyres;

Asbestos;

Waste Plasma Gasification with Molecular dissociation Technology is :

Ecologic

Efficient

Waste Plasma Gasification with Molecular Dissociation Technology is able to

Economic